Reverse Logistics, How does it Work, Barriers, Benefits, and Examples?

Posted on August 19, 2025 by Nur Wachda Mihmidati

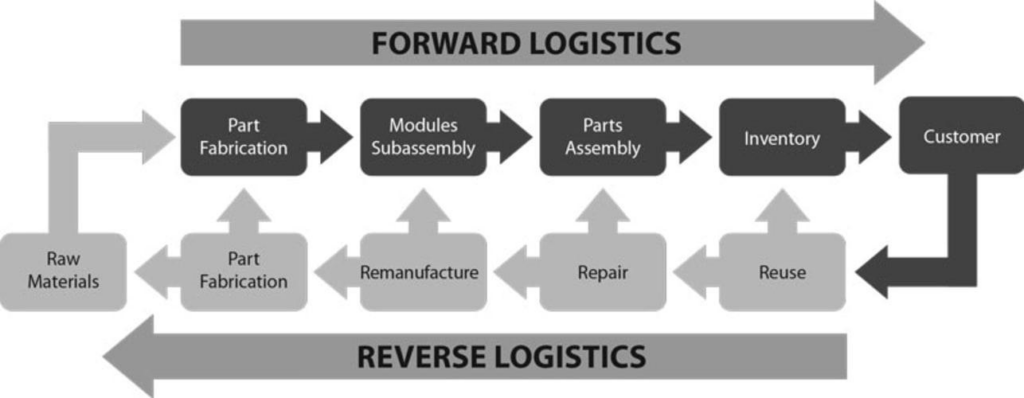

Reverse Logistic is any process that involves moving goods from the customer back to the manufacturer. Reverse Logistic consists of supply chain sectors that process everything that goes back inward through the supply chain or goes ‘backwards’ through the supply chain. Hence the name reverse logistics.

This can include anything from returned goods, disposal/recycling of packaging materials, recycling/responsible disposal of materials from previously sold products, etc.

The full definition of Reverse Logistic, according to the Logistics Management Council, is the process of implementing, controlling, and planning the flow of finished goods, raw materials, and inventory in a cost-effective process. The flow is from the point of consumption (i.e. the customer) to the point of origin (i.e. the producer), to dispose of them properly or to recapture value. Included in this definition is the remanufacturing or repair of goods. Get to know more in this TransTRACK article!

Benefits of Reverse Logistic

how Reverse Logistic is beneficial for both developers and users. There are several benefits to implementing Reverse Logistics processes. With proper planning and execution, reverse logistics can provide many benefits to businesses.

Enhanced Customer Service

Reverse Logistic helps companies improve customer service by providing a way to handle returns and recalls quickly and efficiently. This can help keep customers happy and reduce the amount of negative feedback a company receives.

Enhanced brand image

When a company has excellent management and response capacity, it can provide better customer service. Also, if the returned materials or products become part of the recycling chain, users will feel a sense of respect for the environment, which is increasingly valued in today’s society.

Reducing Environmental Impact

Reverse Logistic helps companies reduce their environmental impact by recycling waste materials and properly disposing of hazardous waste. In addition, efficient reverse Logistics operations can help save energy and resources.

Efficiency Improvement

Reverse logistic can be less efficient than traditional logistics operations due to the need to handle returns and recalls. However, technology has made reverse logistics more efficient in recent years, and there are some tips that companies can follow to further improve the efficiency itself.

How Reverse Logistics Works

Reverse Logistics moves goods from the endpoint of the supply chain at least one step backwards. This process can involve various plans and controls. Some companies prefer to outsource this work.

The reverse Logistic process involves managing the return and purchase of surplus goods and materials. This process is also responsible for handling any leases or repairs. Reverse Logistics varies in different industries, and there are different economic incentives to improve reverse Logistics management.

For example, in the beverage industry, the Reverse Logistics process uses empty tap containers. Beverage production companies want to reclaim the value of their containers by reusing them. This requires transportation planning, shipping load management, and container cleaning.

In the construction industry, Reverse Logistics moves and recycles used materials to new locations. As the construction industry adopts more sustainable practices to reduce waste, there are cost-saving opportunities by using Reverse Logistics.

In the food industry, reverse logistics is responsible for returning packaging materials and pallets. Companies also have to deal with rejected food shipments. Rejections can pose logistical challenges due to delays leading to food spoilage and concerns of tampering. Reverse Logistics Association is developing secure, fast, on-package login codes to provide detailed product information and address these logistical challenges.

Why Reverse Logistics Needs to be Implemented

So why would a manufacturer or retailer set up a reverse Logistics process? What do they get out of it?

Below we discuss five important factors in more detail:

Cost savings

More people are shopping online and return rates are increasing, meaning an efficient returns process can save your business money.

Customer satisfaction

Having a quick and easy returns process increases customer satisfaction and retention.

Value of goods

Reusing returned goods helps manufacturers increase the value of the goods or the sustainability of the supply chain – or both.

Sustainability

Consumers are increasingly concerned with sustainability. Reusing goods achieves greater sustainability and can improve business reputation.

Business insight

A well-organized Reverse Logistics process will provide us with valuable data to help us streamline our operations further.

Barriers to Reverse Logistics

While eCommerce often allows businesses to exist, it complicates Reverse Logistics significantly in several important ways:

1. Fraud

For as long as trade has existed, so have those who seek to manipulate it for their own gain. This is especially true now that fraudulent buyers will purchase goods and then return different or incomplete items: a famous example is game consoles whose cases are returned to the seller containing rocks instead of the valuable tech components that were shipped with them.

2. Time and Cost of Damage

Every second that an item spends in the mail on its way back to the seller or being inspected, repaired, or stored in a warehouse waiting to be resold is an additional cost incurred against the item. Being able to quickly get goods back from consumers and return them to the market quickly is a critical requirement for Reverse Logistics systems.

3. International Shipping

As anyone who has ever tried to ship something overseas knows, the process is complicated and expensive. Businesses will often try to help manage this issue by shipping internationally in batches – but when considering Reverse Logistics, such as consumer returns, it doesn’t make sense for consumers to delay shipping until the item can be paired with someone else going to the same place.

4. Lack of High-Level System

While Reverse Logistics is not a new concept, many eCommerce applications are fairly new on the scene. As a result, there is a relative lack of established high-level systems available for businesses of any size.

5. Law

Different countries and regions have different laws for online return policies, making it difficult to limit our return policies and making it easier for our return policies to be exploited by people on the other side of the world. One solution that some companies are exploring is to have a more generous return policy, which increases sales traffic but also increases pressure on Reverse Logistics. However, a more generous policy also comes with the added benefit of being compatible with all the laws we may encounter.

Reverse Logistics Example

If you already know everything about Reverse Logistics, you can understand some examples of Reverse Logistics below:

- Return of goods by customers

- Return of unsold goods by distribution partners due to contractual requirements

- packaging reuse

- Item repair

- Repair and maintenance as per warranty agreement

- Remanufacture of goods from returned or damaged goods

- Selling goods to the secondary market in response to returns or overstocks

- Recycling and disposal of end-of-life items

Existing and evolving market dynamics, such as higher customer return rates and the need for recycling and reuse, increase the occurrence of these Reverse Logistics events.

Benefits of Reverse Logistics for Companies

The implementation of reverse logistics not only helps companies manage product returns and recycling, but also provides various strategic benefits that have a direct impact on operations, customer satisfaction, and company image:

- Operational Cost Efficiency – By managing product returns, repairs, and recycling in an organized manner, companies can reduce waste and maximize the use of resources.

- Improves Customer Satisfaction – Quick and easy return services make customers feel valued, increasing loyalty and the likelihood of repeat purchases.

- Improves Company Image – Reverse logistics practices that focus on sustainability and environmental responsibility strengthen a company’s reputation as a brand that cares about the environment.

Benefits of Reverse Logistics for Consumers

Reverse logistics is not only beneficial for companies, but also provides direct benefits for consumers. With a structured and environmentally friendly returns system, consumers can experience the following benefits:

- Ease of Product Return – Damaged or unsuitable products can be returned quickly and easily, reducing hassles for consumers.

- Supports Eco-Lifestyle – The process of recycling and managing used products helps consumers contribute to environmental sustainability.

- Cost and Time Efficiency – Efficient return process saves time and cost, making the shopping experience more convenient and practical.

Solutions & Technology to Support Reverse Logistics

To ensure reverse logistics runs effectively and efficiently, companies can utilize various modern solutions and technologies. The implementation of digital systems and integration between platforms allows the management of product returns to be faster, more accurate, and transparent:

Use of Supply Chain Management (SCM) Software

SCM software helps companies manage the entire flow of product returns, from recording returns, checking the condition of goods, to coordination between divisions. With centralized and structured data, companies can make more informed decisions regarding product repair, replacement, or recycling.

Integration with Fleet Management System (FMS)

With FMS integration, product delivery and return pickup can be done more efficiently. The system enables optimal route planning, real-time fleet monitoring, and precise delivery schedule management, resulting in reduced operational costs and faster return times.

Digitization of Returns & Goods Tracking Process

Digitization allows consumers and companies to monitor the status of returns in real-time, from the time a return is submitted until the item arrives at the warehouse or repair center. This transparency not only increases customer satisfaction, but also makes it easier for companies to manage data, track performance, and analyze return trends for future process improvements.

Conclusion

Reverse logistics is not just a process of returning goods, but an important strategy that provides benefits to both companies and consumers. For companies, implementing reverse logistics can improve operational efficiency, customer satisfaction, and sustainable brand image. For consumers, this process offers ease of return, support for eco-friendly lifestyles, and time and cost savings. Technology support, such as supply chain management software, fleet management system integration, and digitization of goods tracking, makes this process more transparent, fast, and accurate. With the right approach, reverse logistics becomes a win-win solution, strengthening the relationship between companies, consumers, and the environment.

FAQ – Reverse Logistics

- How can reverse logistics improve company efficiency?

Reverse logistics helps companies manage product returns, repairs, and recycling in a structured manner, thereby reducing waste, lowering operational costs, and maximizing the use of resources. - What are examples of reverse logistics applications in the industry?

Examples include returning damaged or non-conforming products, collecting packaging for recycling, refurbishing electronics, and managing leftover production in the manufacturing industry. - How is reverse logistics different from forward logistics?

Forward logistics focuses on delivering products from manufacturers to consumers, while reverse logistics focuses on the reverse flow of products from consumers to companies for returns, repairs, or recycling. - How does technology help optimize reverse logistics?

Technology such as supply chain management software, fleet management systems, and digital goods tracking enable efficient, real-time, and transparent management of the returns process, thereby reducing errors and improving customer satisfaction.

Reverse Logistics, as we know, will play an important role in doing the “reverse” work in the supply chain. Well, to help this reverse logistics in making deliveries, of course the company will need good fleet management as well for optimal delivery. To solve this, companies can use TransTRACK’s Fleet Management Systems which can be used to monitor driver behavior, manage vehicle usage, increase fuel efficiency, and improve fleet utility and safety. Start switching to the all in one platform TransTRACK!

Topic :

Recommended Articles

Improving Fleet Safety through Traffic Accident Prevention with ADAS

Featured Product | February 12, 2026

Bahasa Indonesia

Bahasa Indonesia